Some equipment may need to be shut down by turning off power from the breaker or by simply shutting a valve.

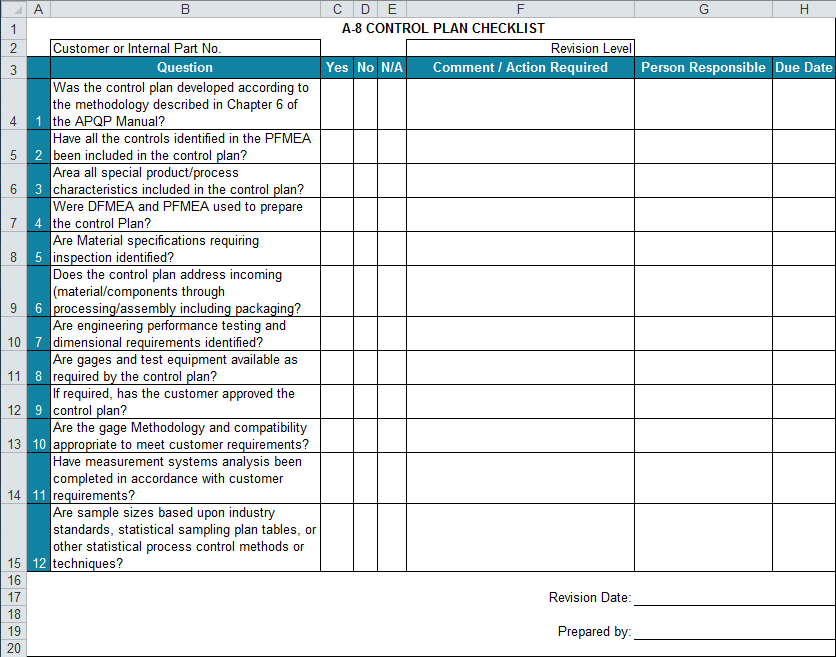

CHECKLIST TO ESTABLISH SPC SYSTEM HOW TO

Inform all the affected employees that the machine or equipment is back in operation.Īlso known as LOTO steps, follow this comprehensive guide on how to properly shut down equipment:.

Restore energy to the machine or equipment.LOTO devices to be removed by the person who applied them.Clear all the tools and place back machine guarding.Lock out the machine or equipment, ensure that shut off is verified and that employees know that it is out of service at the moment.Ensure that all sources of power are isolated before the proper LOTO devices are applied to each energy-isolating device.Primary and possible secondary sources of energy should be identified and de-energized.The responsible persons who will apply the devices should be identified.Ensure that the proper LOTO devices are available for the job.Employees should be informed that a machine or equipment is about to be serviced and that a lock out tag out procedure is being performed.Employees are made aware of their responsibilities during the LOTO and maintenance of the machine.Employees who are not going to work on the maintenance should also clear the area.Check if the area surrounding the equipment has no items that could pose a risk to the workers during the equipment maintenance.Identify the energy sources that could cause harm if not isolated such as electrical, mechanical, hydraulic, pneumatic, chemical, thermal, etc.Identify the machine or equipment that will be shut down and record the purpose of the lockout/tagout such as maintenance or repair.

Here are the main sections of a lock out tag out procedure checklist: Machine/equipment information Lockout tagout procedures can vary depending on the industry or type of machine or equipment. Lock Out Tag Out Procedure Checklist | iAuditor What’s in a Lock Out Tag Out Procedure Checklist? Millions of machine operators and workers are exposed to risks each day due to non-isolated energy sources lock-out tag-out procedure checklists aim to protect workers from those risks. This is done to protect workers against hazards such as accidental energization of equipment or exposure to hazardous energy. What is a Lock Out Tag Out Procedure Checklist?Ī lock out tag out procedure checklist is a tool used by safety officers and managers to ensure that steps are taken to isolate energy sources when servicing industrial equipment or heavy machinery.

0 kommentar(er)

0 kommentar(er)